I. Case Overview

With the continuous development of industrial equipment manufacturing enterprises, with operations throughout the country and even globally, equipment sales have increased and equipment stock market has increased. In the after-market equipment services, there are often difficulties in communication and communication, inaccurate fault responses, backward equipment operation and maintenance management, A series of problems, such as inefficient handling of equipment problems, affect not only the corporate image, but also a large amount of wasted human and material costs.

A weightless feeder manufacturer listed in Wuxi City, Jiangsu Province now has more than 350 domestic and international customers, with a wide distribution of customers, large annual equipment sales, and large equipment market inventory. The subsequent equipment operation and maintenance problems have become prominent, the equipment operation and maintenance workload is huge, and a large amount of human input is still difficult to meet the operation and maintenance requirements. The original offline method of handling problems was inefficient, communication of equipment problems was difficult, troubleshooting was difficult, and operation and maintenance were not timely. Seriously affect the corporate service image.

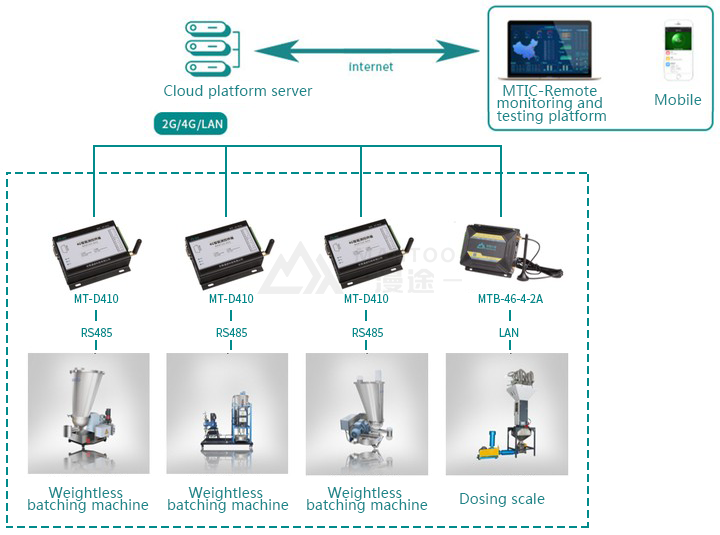

MANTOO, as an industrial IoT service provider with R & D and intelligent manufacturing capabilities in the Yangtze River Delta region, uses wireless transparent transmission and edge computing technology with intelligent acquisition terminals MT-R410 and MT-R4610 according to the needs of the equipment manufacturer. As the core of equipment and sensor acquisition and transmission, it has developed a remote operation and maintenance cloud platform system that integrates equipment online, customer management, and operation and maintenance management. This product helped the factory solve the real-time collection, analysis, early warning of equipment data, customer information management, online feedback of problems, online dispatching, and online disposal. At the same time, the platform and the enterprise were nailed down to achieve unified management. Reduce problem discovery time, improve operation and maintenance efficiency, and improve corporate service image.

II. System architecture diagram

Ⅲ. System functions

-Equipment monitoring: real-time collection of various parameter data of the feeder, support the collection of ordinary board and PLC equipment data at the same time.

-Customer management: Support independent definition of organizational structure, maintenance of multi-layer structures such as equipment vendors, customers, workshops, production lines, and support for multiple role definitions such as equipment vendor administrators, operation and maintenance personnel, customer managers, and customer employees.

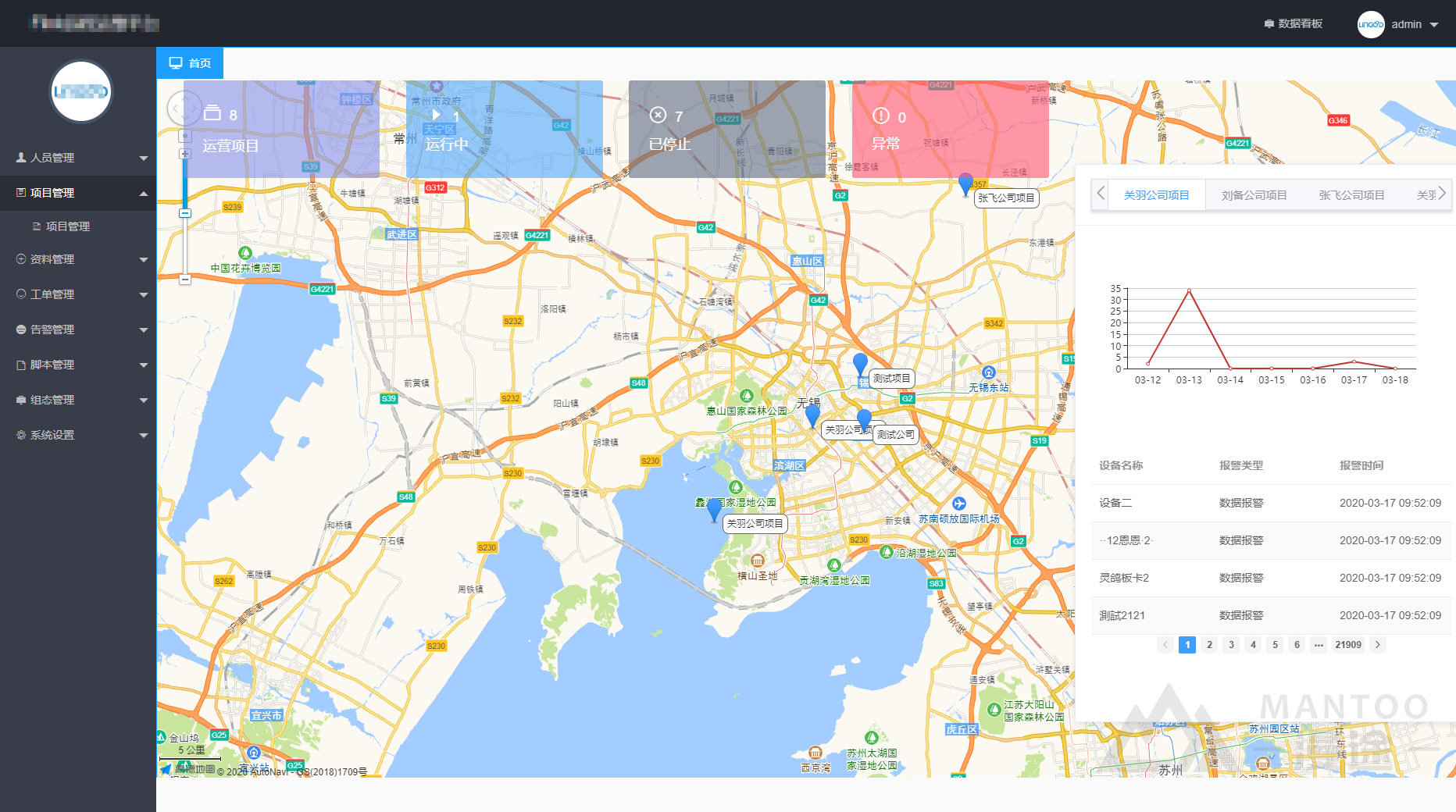

-GIS geographic distribution: Through GIS maps, visually display the distribution of customers, projects, and equipment, and support real-time viewing of alarms and real-time viewing of work orders.

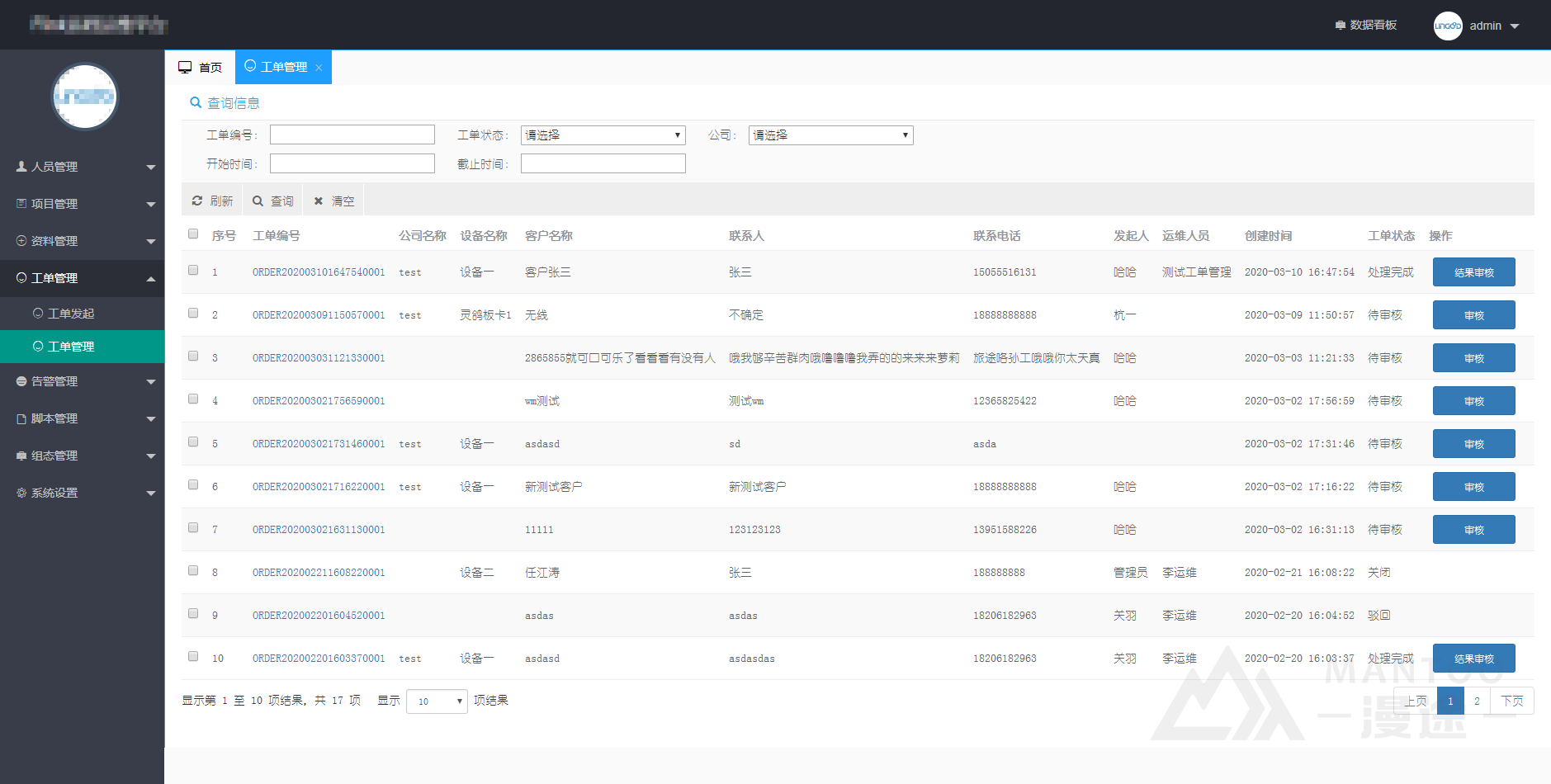

-Operation and maintenance management: Online feedback on issues, generation of work orders, review and dispatch by administrators, operation and maintenance personnel receive tasks through Nail, WeChat and other platforms, online processing, combined with Nail Daily report for task execution feedback, comprehensive management and control of O & M Improve operation and maintenance efficiency.

-Data management: perfect customer data management, unified upload by equipment vendors, customers, operation and maintenance personnel can download and view through PC, WeChat, Dingding, etc. anytime, anywhere.

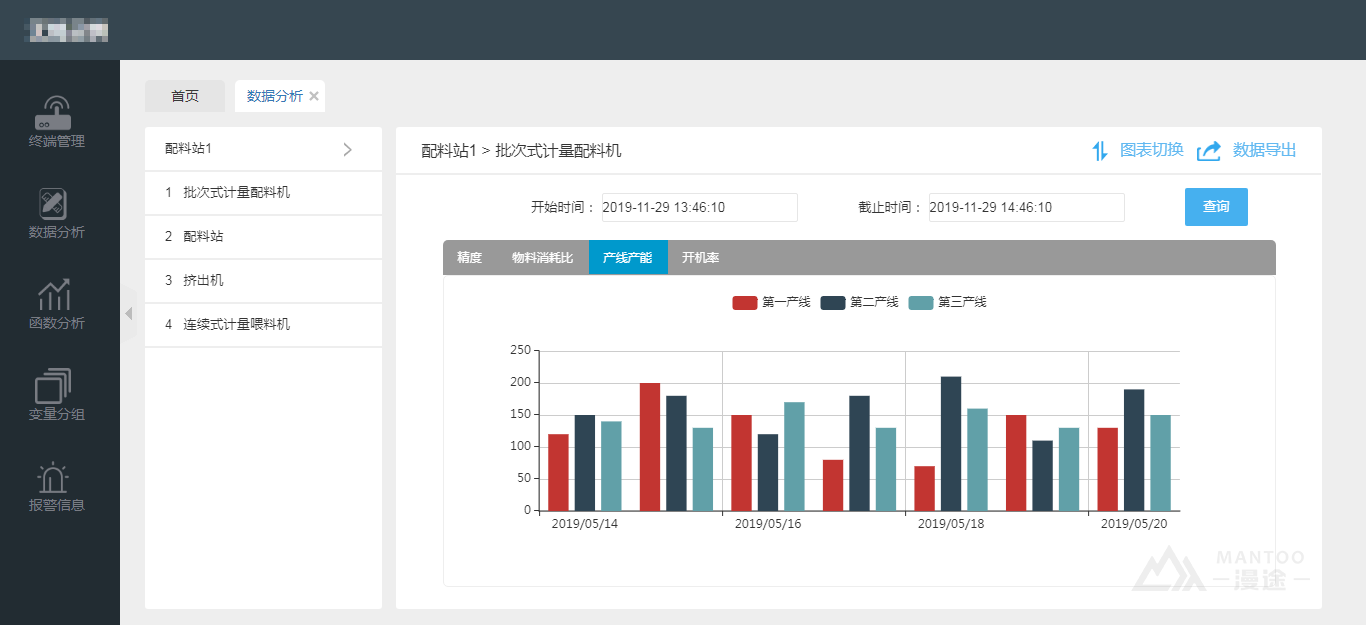

-User-defined analysis: The system supports user-defined algorithm analysis for device data collection points, and supports variable grouping calculation.

-Real-time alarm: The system automatically detects abnormal conditions such as equipment alarms and data overruns, immediately triggers an alarm mechanism, and notifies corresponding management personnel, operation and maintenance personnel through the system platform, WeChat, and SMS.

-Rights management: The system supports user and role management, and can customize the organizational structure. It also supports the isolation of menus, buttons, devices, and data permissions, and assigns them independently to ensure data security.

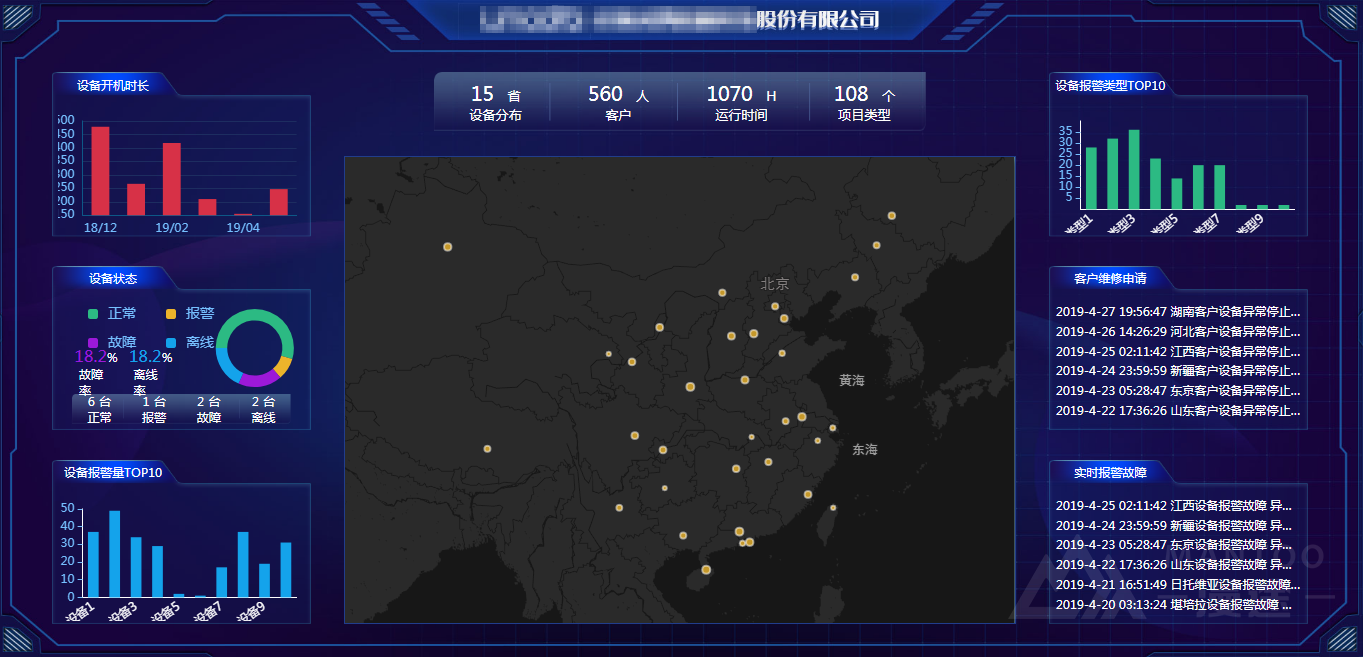

Ⅳ. Software system interface

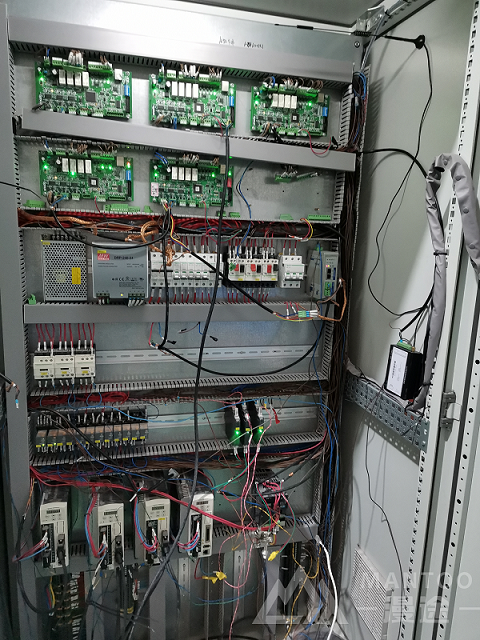

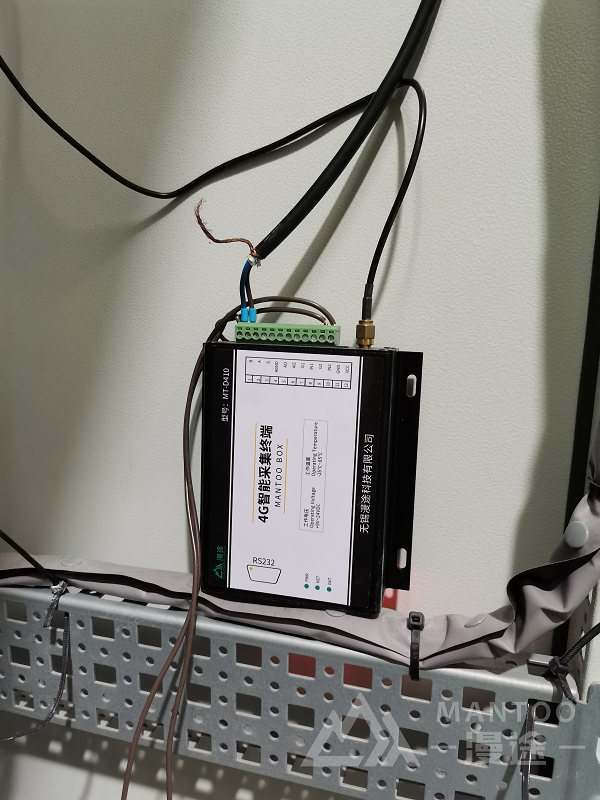

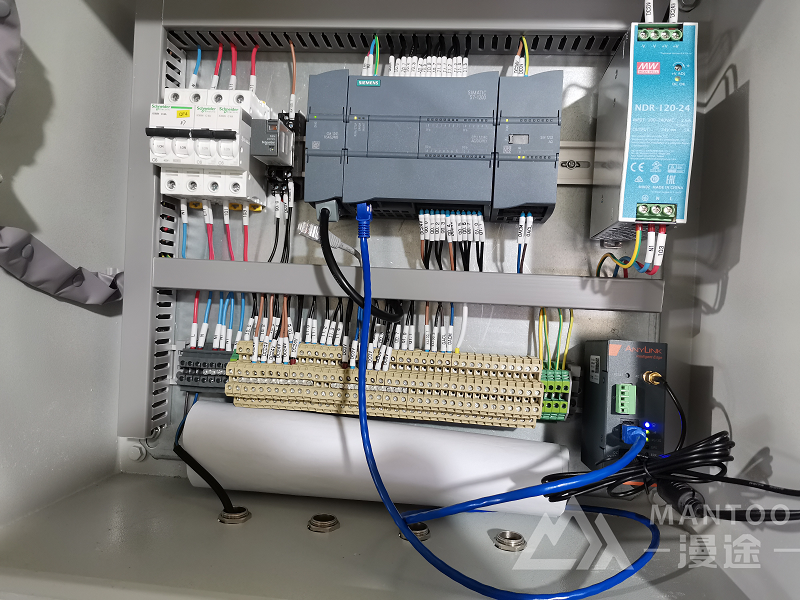

Ⅴ. Field application photos

Batching machine board collection

Batching scale PLC acquisition

Field Control Center