I. Case Overview

With the expansion of the scale of traditional manufacturing enterprises, the types of equipment continue to increase. The troubleshooting and maintenance of traditional equipment mostly rely on the company employees to go to the field to complete the service. The manual management method can no longer meet the human, machine, material, Effective management of environmental monitoring and testing will not only increase the maintenance and maintenance costs of workshop equipment, but also greatly affect the production schedule and personnel management of the workshop.

At present, a large domestic heat treatment plant in Yongkang City, Zhejiang Province currently has internationally advanced Japanese imports of vacuum carburizing furnaces, energy-saving and environmentally friendly isothermal salt bath quenching furnaces, pre-vacuum multi-purpose furnaces, vacuum hydrocarbon cleaning machines and other equipment, as well as advanced domestic equipment. Horizontal large-scale auto parts heat treatment multi-purpose furnace, controlled atmosphere multi-purpose furnace, rolling rod furnace, oil-cooled double-chamber vacuum furnace, large continuous mesh belt furnace, high and medium frequency induction heating equipment and other advanced heat treatment production equipment more than 100 sets (sets) ), With the continuous increase in the type and quantity of equipment, the manual management method has been unable to meet the effective management of man, machine, material, method, environment, and measurement in the production process. Enterprises hope to be able to use advanced automation and information technology industrial Internet of Things technology to monitor these devices around the clock to ensure safe operation, while taking into account the environment and energy consumption.

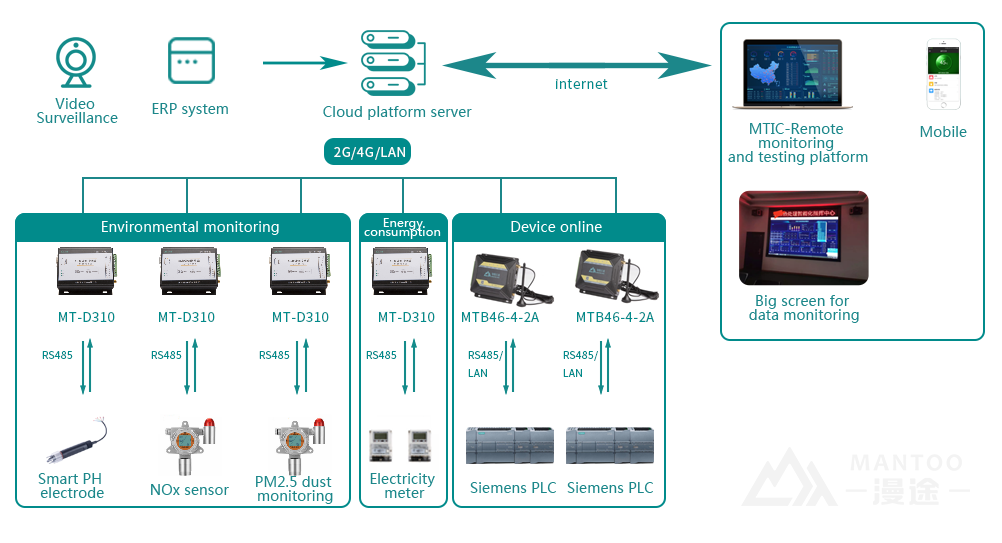

MANTOO, as an industrial IoT service provider with R & D and intelligent manufacturing capabilities in the Yangtze River Delta region, uses the cloud platform, wireless transparent transmission, and edge computing technology in conjunction with intelligent acquisition terminals MT-D310 and MTB- R4642, with sensors and equipment acquisition and transmission as the core, has developed a smart factory online cloud platform system that integrates equipment online, environment online, energy consumption online, and ERP system integration. This product helps the factory to solve the real-time collection, analysis, and early warning of equipment data, environmental data, and energy consumption data, and centralized management of various large equipment. Effectively improve the overall operating efficiency of the enterprise and reduce its operating costs.

II. System architecture diagram

Ⅲ. System functions

※ Equipment monitoring: Real-time collection of real-time operating status, various parameters, fault alarms and other data of various heat treatment equipment such as main furnace, tempering furnace, salt bath furnace, nitriding furnace, and multi-purpose furnace.

※ Environmental monitoring: Real-time collection of factory exhaust gas and waste water pollutant content, including PM2.5, nitrogen oxides, PH, etc., can customize alarm rules according to emission standards to achieve factory environmental monitoring.

※ Energy consumption monitoring: Real-time collection of energy meter, transformer and other energy-consuming equipment data, including power consumption, ABC three-phase current, voltage, active power, power factor, etc., from the factory, workshop, production line, day, month, and year dimensions Energy consumption statistics and analysis to achieve energy consumption monitoring.

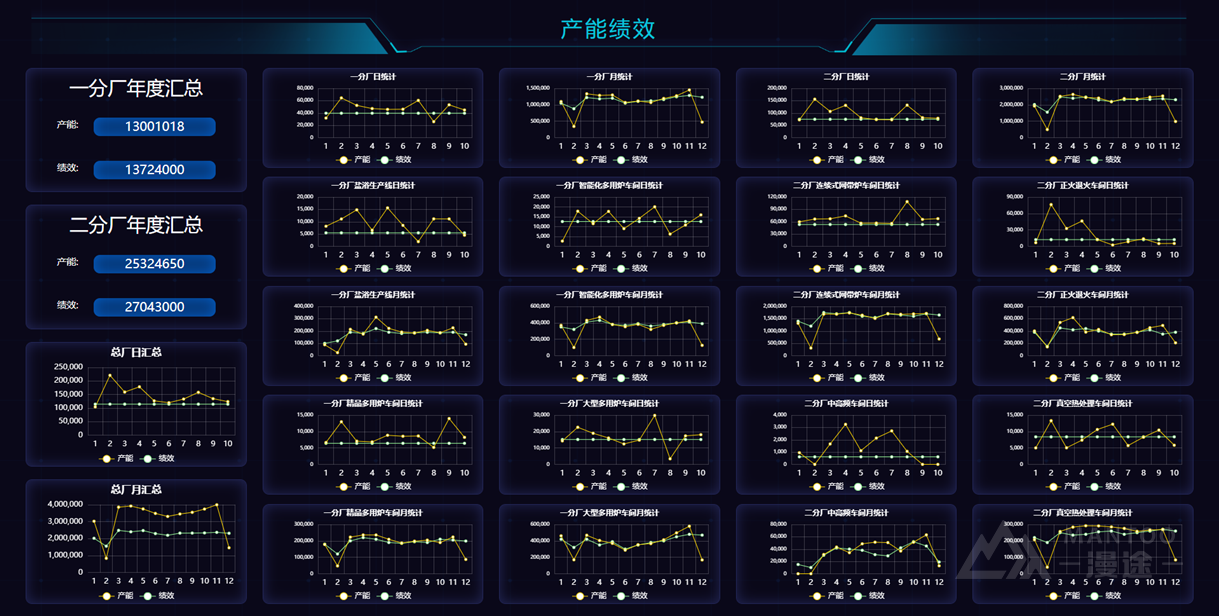

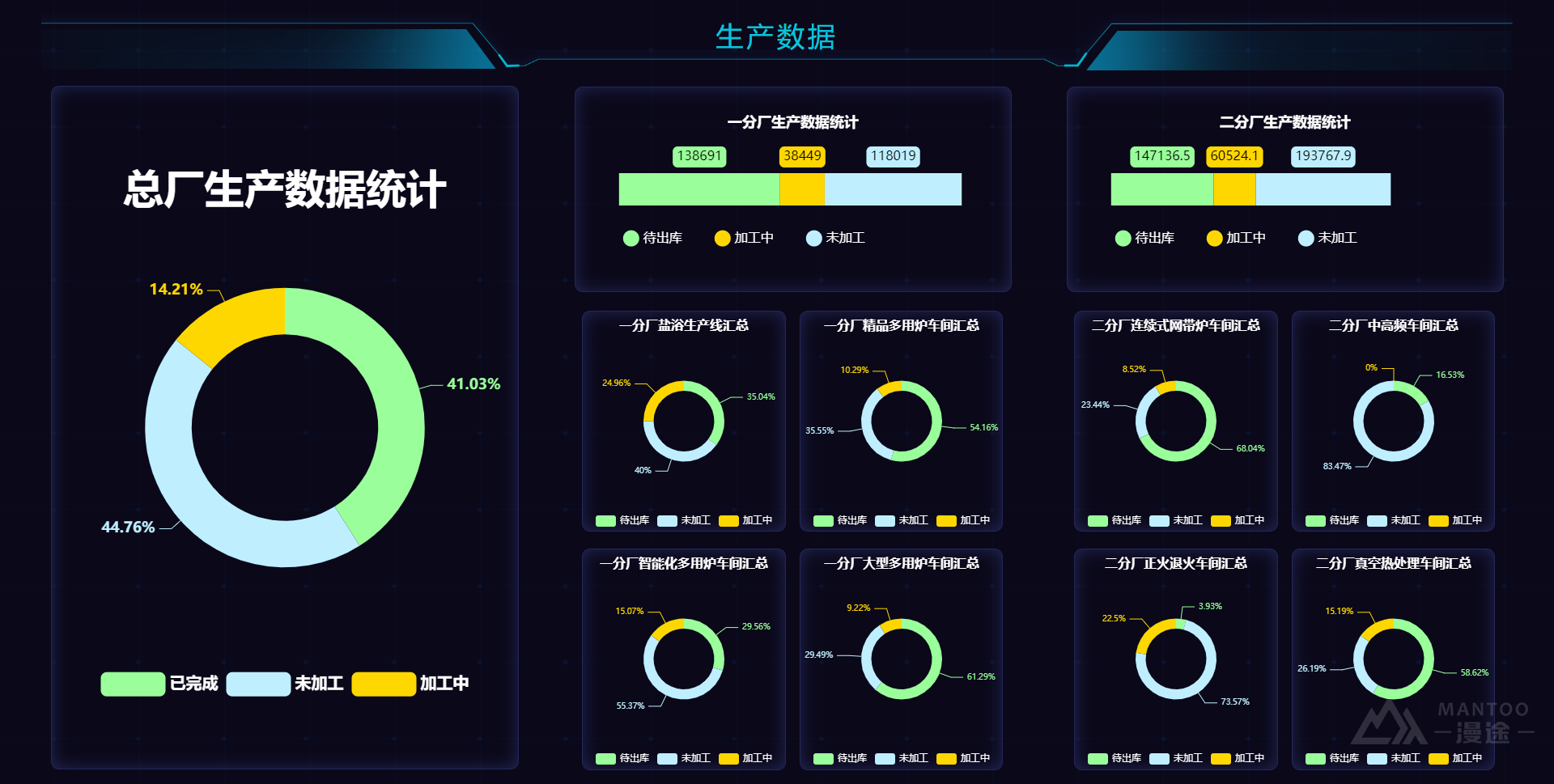

※ Capacity performance: Connect with enterprise ERP system, obtain daily, monthly and annual input and output of factories, workshops, and production lines, and combine energy consumption monitoring to achieve capacity performance statistics and analysis.

※ Custom analysis: The system supports custom algorithm analysis for equipment data collection points, and supports variable grouping calculation.

※ Real-time alarm: The system automatically detects abnormal conditions such as equipment alarms and data overruns, immediately triggers an alarm mechanism, and notifies the corresponding management personnel through the system platform, WeChat, and SMS.

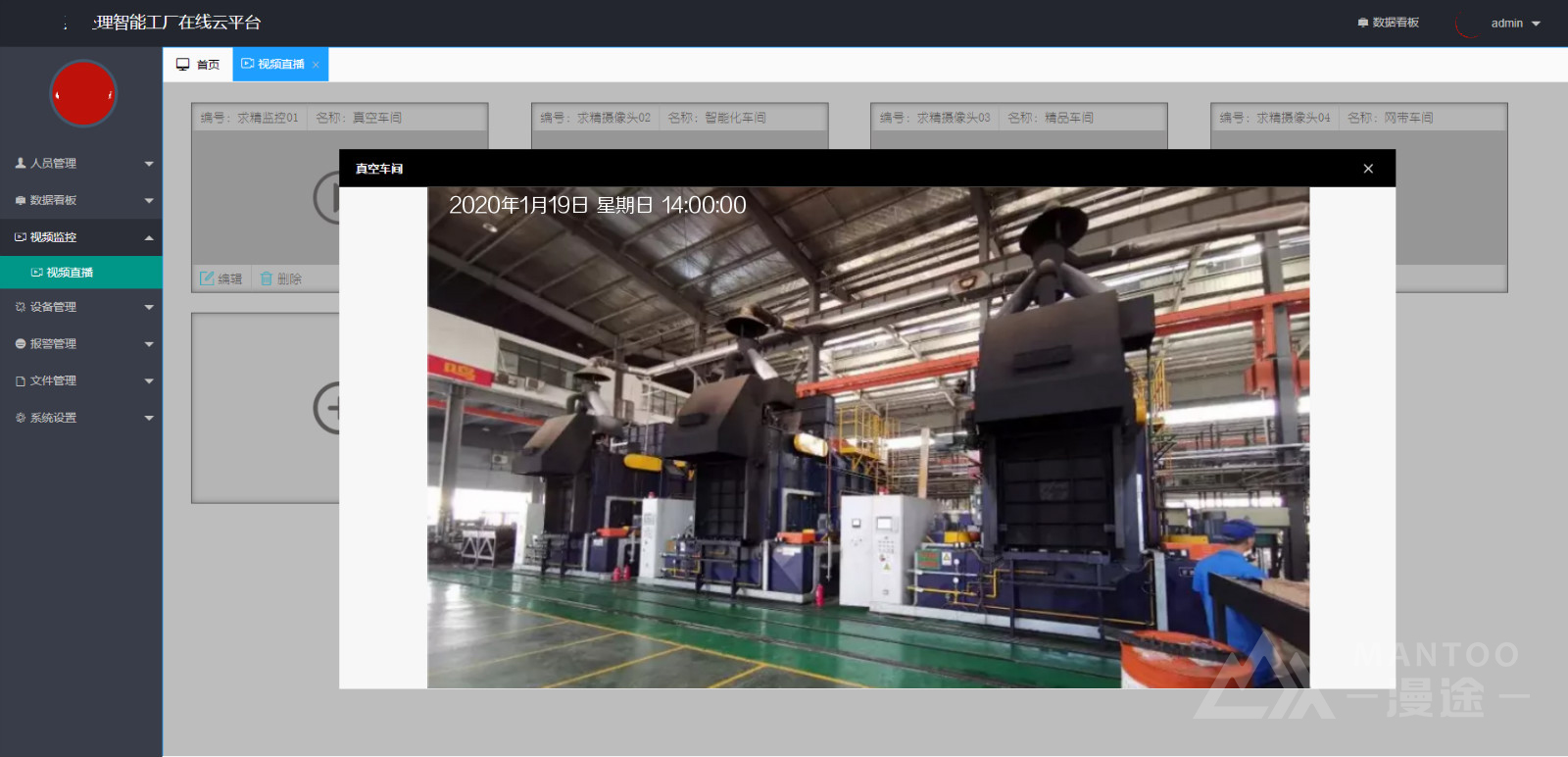

※ Video linkage: The system supports docking with live video equipment to achieve live video. When a device alarm occurs, the video points corresponding to the device are automatically linked for real-time picture adjustment.

※ Rights management: The system supports user and role management, can customize the organizational structure, supports menus, buttons, devices, and data rights isolation, independent distribution, and fully ensure data security.

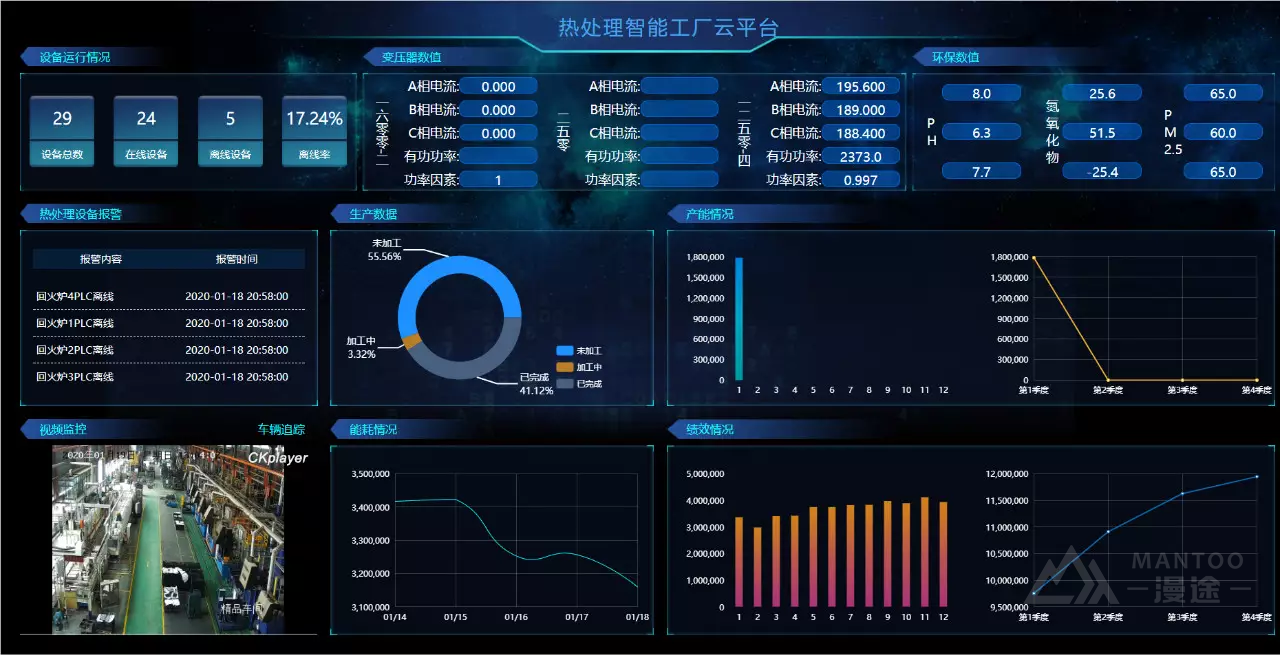

Ⅳ. Software system interface

Factory Cloud Platform Overview Map

Equipment Capacity Performance Curve

Environmental Online Monitoring Data

Energy Consumption Online Data

Equipment Online Data Monitoring

Distribution Chart of Production Data of the Main Plant

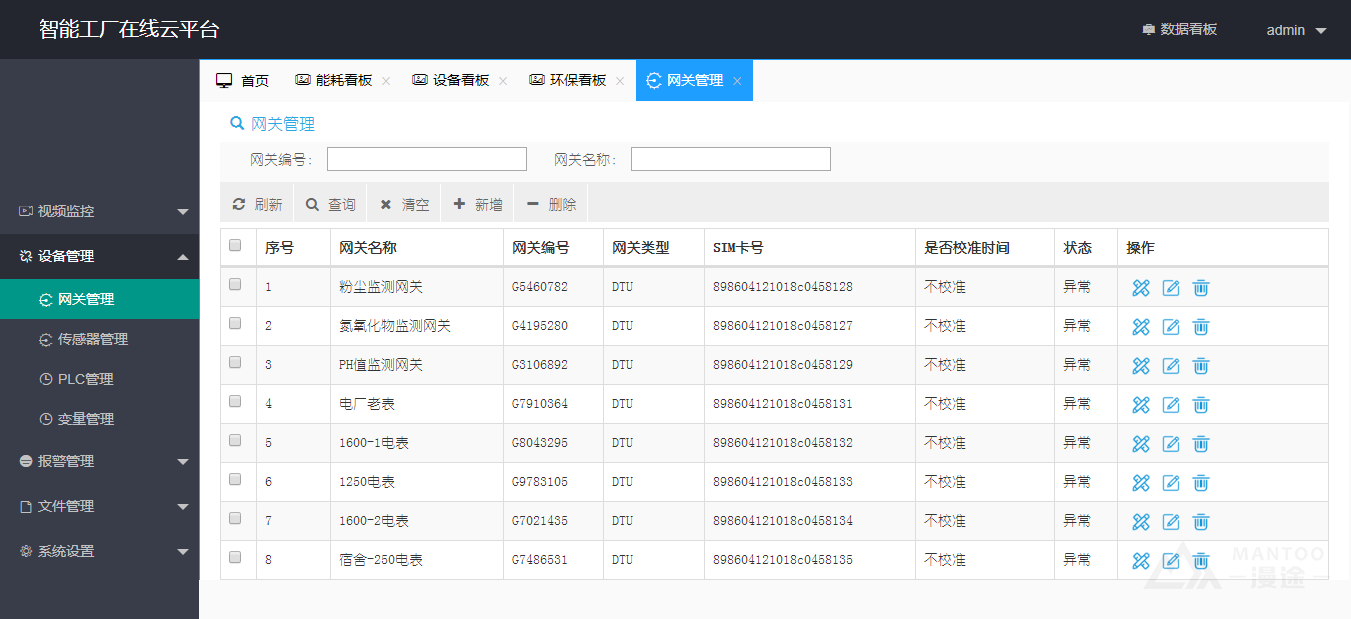

Gateway Management Diagram

Real-time Video Surveillance Map

Add Gateway Configuration Diagram

PLC Equipment Management Diagram

Alarm Management Diagram

Ⅴ. Hardware Product Introduction

Product introduction:

MT-D310 GPRS intelligent acquisition terminal series is a high-performance wireless acquisition device that integrates acquisition and wireless data communication. It adopts high-performance industrial-grade wireless modules, high-performance industrial-grade processors, metal enclosures and system security isolation to support a variety of With RS485 sensor access, suitable for industrial control field applications.

In the system, it is used to collect data of environmental sensors and energy consumption data of meters, and upload it to the cloud platform steadily and quickly.

Product introduction:

MTB46-4-2A is a high-performance measurement and control device that integrates RS485, USB interface, digital input, relay output functions, supports LAN port and wireless data communication, supports RS485 interface device access, supports data storage and acquisition protocols. Definition to meet various industrial application scenarios.

In the system, it is mainly used to collect the data of each boiler PLC such as vacuum furnace and upload it to the cloud platform.

Ⅵ. Field application photos

Monitoring Center Data

Online Collection of Equipment Lines to Collect Field PLC Data

Online Collection of Equipment Lines to Collect Field PLC Data

PM2.5 Monitoring

Waste-water pH Monitoring

NOx Monitoring

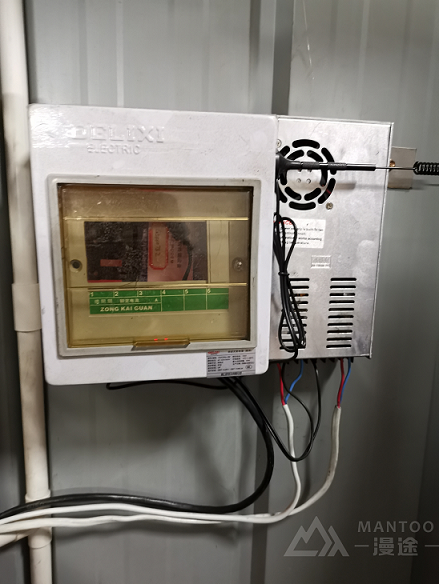

Collection of Workshop Energy Consumption Data

I. Customer Evaluation

The person in charge of the factory floor says:

This system organically connects all the links of the workshop together, and can easily grasp the operating status and efficiency of the workshop in the monitoring center, and immediately feedback some important events such as equipment failure, environmental alarms, and excessive energy consumption, which greatly facilitates management. In addition, the supporting WeChat program on the system can not only check and pay attention on the mobile terminal, but also provide great help for the factory's new media promotion. At present, some customers are paying attention to our factory WeChat public account to check the progress and quality of their orders Retrospective, the reputation of the company's products and services has greatly improved. The key is that the system and platform cooperate with some automation equipment and successfully won the smart workshop project, which is also a benchmark and a model in the industry!